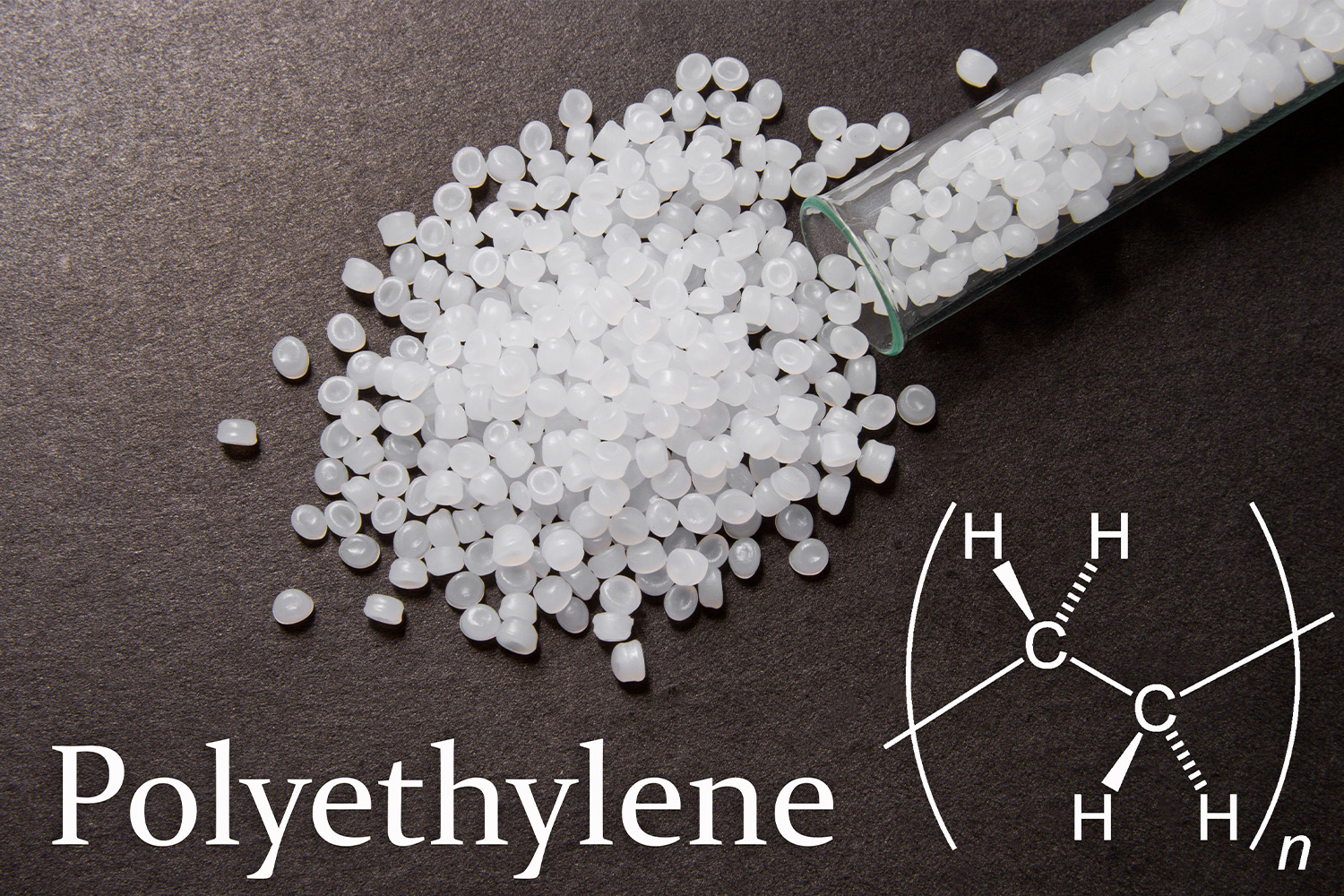

Polyethylene

Polyethylene (PE) is the most widely used commodity plastic. It is available in many different forms depending on the configuration of its molecular chain. Polyethylene is classified as a homopolymer due to the fact that it is made from repeated units of one single type of molecule, ethylene. Polyethylene is a tough, abrasion-resistant plastic that can be easily formed using techniques like injection molding and blow molding. It is typically used for bottles, water tanks, or plastic bags.

Polyethylene is a thermoplastic product, meaning it is made of polymers that become liquid at high temperatures and solidify once cooled. This makes PE highly durable and useful in many applications.

PE is the world’s most commonly used consumer packaging plastic, and it comes in many different forms, each with unique characteristics and uses.

Common Applications of Polyethylene

Polyethylene and its variants are some of the most widely used plastics and can be found in almost every major industry. The common applications of polyethylene are:

- Bottles

- Water tanks

- Food containers

- Bags

- Pipes and pipe fittings

- Flexible films

- Medical implants

- Ropes

- Fishing nets

- Wear-resistant liners for chutes

High-Density Polyethylene (HDPE)

HDPE is a versatile plastic made from petroleum. Due to its high melting point in the range of 120 to 130°C, HDPE is highly malleable and, once cooled, remains rigid under most conditions.

With a high strength-to-density ratio, HDPE is a lightweight, tough, and durable plastic. Unlike its flexible and transparent counterpart LDPE, HDPE is denser and more opaque.

HDPE is used to manufacture the following products:

- Bleach bottles

- Milk jugs

- Cutting boards

- Piping

- Wood-plastic composites

- 3D printing filament

- Water bottles

- Shampoo bottles

Low-Density Polyethylene (LDPE)

LDPE is a thermoplastic made from the monomer ethylene. LDPE is softer, more transparent, and more flexible than its sister plastic HDPE. However, its lower melting point of about 110°C makes it unsuitable for high-heat environments, as it will become soft and weak.

LDPE is most often used in film applications because of its toughness, transparency, and flexibility. Its resistance to acids, bases, and vegetable oils makes it an ideal plastic for food applications.

LDPE is commonly used for the following products:

- Food containers

- Shrink wrap

- Pallet wrapping

- Grocery bags

- Plastic film

- Squeezable or single-use plastic bottles

- Plastic containers and tubs

Our Products of Polyethylene

HDPE

LDPE

HOW A PRODUCT IS DELIVERED

Voptasch oversees the transportation of cargos connecting suppliers and producers with points of consumption. The Shipping and Chartering Desk at Voptasch arranges transportation issues, both for suppliers and for customers.

It’s our commitment that costumers’ products shall be delivered on requested time and quality.

Our business model relies on being able to deliver products consistently, safely and responsibly. If we were to supply off-specification products we might suffer financial penalties or find them rejected by customers.

The reputational and societal consequences could be even more significant.