Bitumen VG

Viscosity Grade Bitumen (Asphalt) is a Bitumen grade mostly used as a Paving Grade and it’s suitable for road construction and for the asphalt pavements producing with premier attributes. VG Bitumen is usually used in the production of hot mix asphalt.

Viscosity Grade Bitumen is petroleum grade bitumen, which produced from fractional vacuum bottom which comes from distillation of crude oil, which feasible appliance and behavior changes according to its temperature.

Viscosity Grade bitumen is specified by ASTM Standard D3381-09 and AASHTO M226-80 (2008). VG Bitumen specifications cover by Viscosity at 60 ̊C (140 °F).

We have two methods of grading:

- Standard Viscosity Grade Bitumen (AC-Grades), in which the Viscosity of the standard bitumen (asphalt) is measured at 60 ºC (140 ºF).

- RTFOT Viscosity Grade Bitumen (AR-Grades), in which the Viscosity of bitumen (asphalt) is measured at 60 °C (140 °F) after the roll on thin film oven test.

Viscosity grade bitumen has a thermoplastic feature which causes the material to soften at high temperatures and to harden at lower temperatures. This temperature viscosity relevance is significant when specifying the performance parameters such as the adhesion, rheology, durability and application temperatures of bitumen. In the Viscosity Grade Bitumen specifications, the most important emphasizes is based on the Bitumen ductility.

Viscosity Grade Bitumen Uses

VG-10 BITUMEN

VG-10 is mostly used in spraying applications such as surface dressing and Paving in very cold climate instead of 80/100 penetration bitumen grade. It is also used to produce Bitumen Emulsion and Modified Bitumen products.

VG-20 BITUMEN

VG-20 is used for paving in cold climate & high altitude regions.

VG-30 BITUMEN

VG-30 is especially used to construct extra heavy duty Bitumen pavements that need to tolerate significant traffic loads. It can be used instead of 60/70 penetration bitumen grade.

VG-40 BITUMEN

VG-40 is used in highly stressed areas such as intersections, near toll booths and truck parking lots instead of 30/40 penetration grade. Because of higher viscosity, stiffer Bitumen mixes can be produced to amend resistance to shoving and other problems related to higher temperature and heavy traffic loads.

Voptasch has the capability to supply customers a wide range of Iran Bitumen viscosity grades such as VG 10, VG 20, VG 30, VG 40.

Product Specifications

Viscosity Grade Bitumen

Specification

|

|

VG40 |

VG30 |

VG20 |

VG10 |

Test Method |

|

Absolute Viscosity at 60°c, Poises |

Min.3200 |

Min.2400 |

Min.1600 |

Min.800 |

IS 1206 (Part 2) |

|

Kinematic Viscosity at 135°C, cSt |

Min.400 |

Min.350 |

Min.300 |

Min.250 |

IS 1206 (Part 3) |

|

Flash Point (Cleveland Open Cup), °C |

Min.220 |

Min.220 |

Min.220 |

Min.220 |

IS 1209 |

|

Solubility in trichloroethylene, % |

Min.99 |

Min.99 |

Min.99 |

Min.99 |

IS 1206 |

|

Softening Point (R&B), °C |

Min.50 |

Min.47 |

Min.45 |

Min.40 |

IS 1205 |

|

Penetration@25°C(1OOg,s sec.),0.1 mm |

40-60 |

50-70 |

60-80 |

80-100 |

IS 1203 |

Tests on residue from thin film oven Tests/RTFOT

|

i) Viscosity ratio at 60°C |

Max.4.0 |

Max.4.0 |

Max.4.0 |

Max.4.0 |

IS 1206(part 2) |

|

ii) Ductility at 25°C, cm, after thin film oven test |

Min.25 |

Min.40 |

Min.50 |

Min.75 |

IS 1208 |

|

Specific Gravity@ 27 /27 °C |

Min.0.99 |

Min.0.99 |

Min.0.99 |

Min.0.99 |

IS 1202 |

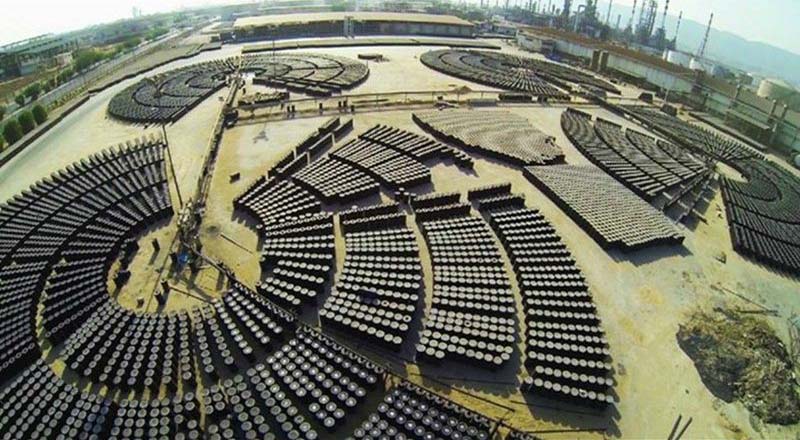

HOW A PRODUCT IS DELIVERED

Voptasch oversees the transportation of cargos connecting suppliers and producers with points of consumption. The Shipping and Chartering Desk at Voptasch arranges transportation issues, both for suppliers and for customers.

It’s our commitment that costumers’ products shall be delivered on requested time and quality.

Our business model relies on being able to deliver products consistently, safely and responsibly. If we were to supply off-specification products we might suffer financial penalties or find them rejected by customers.

The reputational and societal consequences could be even more significant.