Bitumen 85-100

It’s kind of Bitumen which is provided during the process of oxidation of vacuum bottom the Bitumen production feedstock that derives from distillation tower residue in vacuum oil refineries at the Bitumen production unit. in which its penetration points become between 80/100.

Bitumen Penetration Grade 80/100 is a standard penetration grade Bitumen usually used as a Paving Grade Bitumen suitable for road construction and for the production of asphalt pavements with superior properties. This grade of Bitumen is mainly used in the manufacture of hot mix asphalt for bases and wearing courses.

Bitumen 80/100 is one of the most used bitumen grades and basic material for all alternative bituminous products.

Voptasch Penetration Grades of Bitumen is produced from Vacuum Residue, which is blown by hot in the Biturox Blowing Unit; The fully automated process runs continuously resulting in a constant and homogeneous finished product quality.

Voptasch Penetration Grade Bitumen can be supplied in any grade and are designated by two numbers to indicate the mid-points of their penetration ranges. The penetration grade bitumen has a thermoplastic property which causes the material to soften at high temperatures and to harden at lower temperatures. This unique temperature-viscosity relationship is important when determining the performance parameters such as the adhesion, rheology, durability and application temperatures of bitumen.

Requirement for Asphalt cement ASTM 0946

Product Specifications Bİtumen 85-100

|

Analysis |

Unit |

Limit |

Test Method |

|

Density@25°C |

kg/m³ |

1010-1050 |

ASTM D70 or D3289 |

|

Penetration @ 25°C |

mm/10 |

85-100 |

ASTM D5 |

|

Softening point |

°C |

42 min |

ASTM D36 |

|

Ductility@ 25°C |

cm |

100 min |

ASTM D113 |

|

Loss on heating |

wt% |

0.5 max |

ASTM D6 |

|

Drop in penetration after heating |

% |

20max |

ASTM D5 |

|

Flash point |

°C |

230 min |

ASTM D92 |

|

Solubility ln Trichloroethylene |

wt% |

99.0 min |

ASTM D2042 |

|

Spot test |

---- |

Negative |

AASHTO T102 |

|

DynamicViscosity@60°C |

Pa.S |

100±20 |

ASTM D2171 |

|

Kinematic Viscosity@135°C |

cSt |

250 min |

ASTM D2170 |

|

Wax Content |

% |

2max |

DIN EN 12606-1 |

Tests on residue from thin film oven Test (ASTM D1754)

|

Retained Penetration after (T.F.O.T), % |

% |

47 min |

ASTM D5 |

|

Ductility, (25°C), 5cm/min, cm after TFOT |

cm |

75 min |

ASTM D113 |

|

Viscosity @ 60°C |

Pa.S |

500 max |

ASTM D2171 |

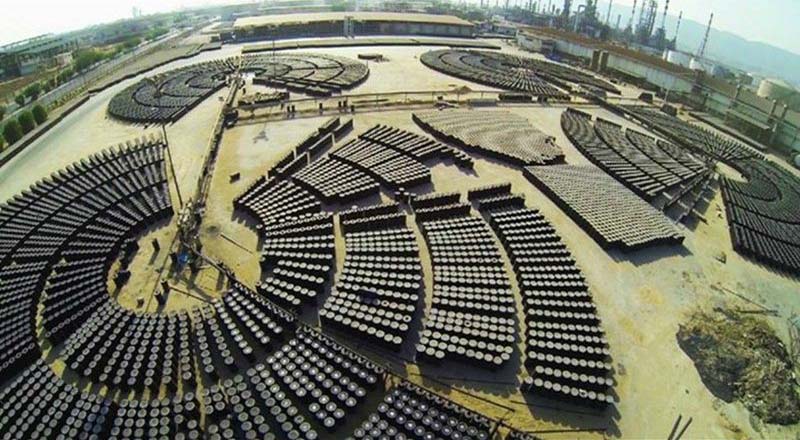

HOW A PRODUCT IS DELIVERED

Voptasch oversees the transportation of cargos connecting suppliers and producers with points of consumption. The Shipping and Chartering Desk at Voptasch arranges transportation issues, both for suppliers and for customers.

It’s our commitment that costumers’ products shall be delivered on requested time and quality.

Our business model relies on being able to deliver products consistently, safely and responsibly. If we were to supply off-specification products we might suffer financial penalties or find them rejected by customers.

The reputational and societal consequences could be even more significant.